SEA Upgrades Keep Travelers Moving and On-Time

Upgrades to SEA BHS Reduces Downtime

Case Study | Seattle-Tacoma International Airport improves baggage handling system’s availability and reliability to keep travelers moving and on-time.

Challenge

- Handle increased passenger capacity by more than double to 2,600 passengers per hour expected over the next several years while improving the baggage handling system availability at Seattle-Tacoma International Airport (SEA)

Solutions

- Stratix® 5400 Using Device Level Ring Dynamic Host Configuration Protocol (DLR-DHCP)

- PowerFlex® 525 Drive-In-A-Box

- One network utilizing EtherNet/IP™ design is a first of its kind application at an airport

- Automatic device configuration (ADC) for quick, automatic, dynamic and centralized management for the distribution

Results

- Highly reliable systems reduce unplanned downtime

- A fully redundant system with no single point of failure to alleviate downtime

- System allows the airport to easily expand baggage handling operations to meet growing global travel demand

- Airports are finely orchestrated logistical operations, moving people, planes and products safely, securely and without delay.

Even the smallest hiccup can create chaos, so companies like ControlTouch, a solutions integrator, specialize in designing systems for airports that deliver baggage to passengers at destinations all over the world.

An advanced system is crucial to seamless operation at SEA Airport. More than 50 million people passed through SEA in 2019. SEA has been the fastest growing airport in the U.S. in the last five years.

The airport needs a flawless baggage handling system (BHS) to maintain excellent traveler satisfaction and meet additional Transportation Security Administration (TSA) requirements with explosive detection system (EDS) machines for improved security and passenger safety.

Decentralized Strategy

Decentralized Strategy

The airport wanted to move its BHS to decentralized control with a safe and redundant system. This would improve customer satisfaction – ensure that the system was always available – and allow the airport to continue to grow to meet global travel demands.

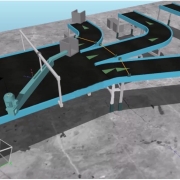

SEA’s engineering firm worked with ControlTouch and Rockwell Automation to develop a system that did not have a single point of failure in the decentralized system. For the Baggage Optimization Project in the domestic terminals and the International Arrival Facility Project, Rockwell Automation, with BNP Associates and ControlTouch, developed the Drive-In-A-Box (DIAB).

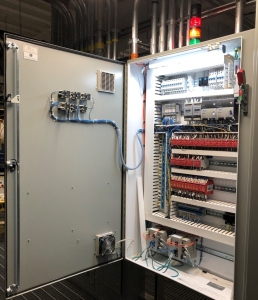

The DIAB configuration uses PowerFlex 525 drives with automatic device configuration (ADC), allowing for the non-disruptive replacement of a drive within minutes – maintaining a positive traveler experience by reducing the risk of potential baggage delays.

With so much at stake in this design, the team worked to prove the network using a redundant PLC arrangement while keeping the DIAB as small as possible. The system uses more than 300 DIABs, each with a PowerFlex 525 variable frequency drive, rotary disconnect, pilot devices, 1799E I/O card, terminal blocks and quick cord set connectors at the bottom.

The system also uses Stratix® 5400 using Device Level Ring (DLR) dynamic host configuration protocol to function as a server that provides automatic IP address assignment. This capability helps to reduce the amount of time required to replace failed BHS components.

The system also uses Stratix® 5400 using Device Level Ring (DLR) dynamic host configuration protocol to function as a server that provides automatic IP address assignment. This capability helps to reduce the amount of time required to replace failed BHS components.

The feature automatically downloads the IP address and all the configuration of the replaced component, so the system can be running again in under 10 minutes. In the past, this required maintenance or operations to manually enter the data – taking 30-45 minutes. The result of the new solution is improved customer satisfaction and reduced lost baggage costs.

Offering one network utilizing EtherNet/IP™ design is a first-of-its-kind application in an airport, offering a best-practice for minimizing multiple communication networks, network converters and data conversions.

As a result, SEA staff does not require training on multiple networks or how data is mapped from one EtherNet/IP™ to another. In addition to reduced training time, ControlTouch has reduced programming and integration costs while taking advantage of common off the shelf (COTS) equipment, providing compatibility between OT and IT.

Reducing Downtime

Redundant systems alleviate downtime by providing system availability.

SEA improved recovery time by simplifying field device replacement, by utilizing the standard features of DLR-DHCP and ADC included in the DIAB components. By eliminating a single point of failure and relying on DLR, redundant switches and controllers, SEA’s BHS can continue to run, as the network is self-healing.

Maintenance can seamlessly replace defective or down system parts without the need for programming/configuration devices (plug and play), achieving the airport’s goals of greater efficiency and less downtime in its BHS.

Summary

These solutions developed by Rockwell Automation with ControlTouch and BNP Associates increased the handling capacity and optimized the baggage handling system availability at SEA. The new, highly reliable, and fully redundant systems alleviate downtime resulting in delivering bags where they need to go and keeping people moving.