How we use Emulate3D to reduce risk, time, and costs.

March 2020

In the material handling and baggage handling world, engineers work together at the project site to install, program, test, and debug the system for weeks or even months. This process is called commissioning. Commissioning is the process of assuring that all systems and components of a solution are operating to meet industry standards and the expectations of the customer or end-user.

There are several challenges with commissioning from disturbing operations to thoroughly testing the system, which can end up with late and over-budget projects.

Simulation and Emulation over the years have played a significant role in addressing the challenges in commissioning. The marriage of these two has given birth to Virtual Commissioning.

Virtual Commissioning is a more effective and less expensive way to commission.

Here are the five benefits of Virtual Commissioning.

- More robust system – With Virtual Commissioning, you can test earlier in the process and at the same time as a system is being built. This allows you to catch things quickly, leaving more options with design choices and having more time for testing.

- Computer-based – Being computer-based, it makes testing repeatable, safer, and cheaper than commissioning live.

- Bring what-if scenarios to life– We can analyze system throughput and identify bottlenecks to help you make better decisions.

- Less disruption – Having the opportunity to test early, often, and run what-if scenarios will reduce the amount of time PLC engineers spend on-site.

- Train operators – Operating training can happen without disrupting the current system.

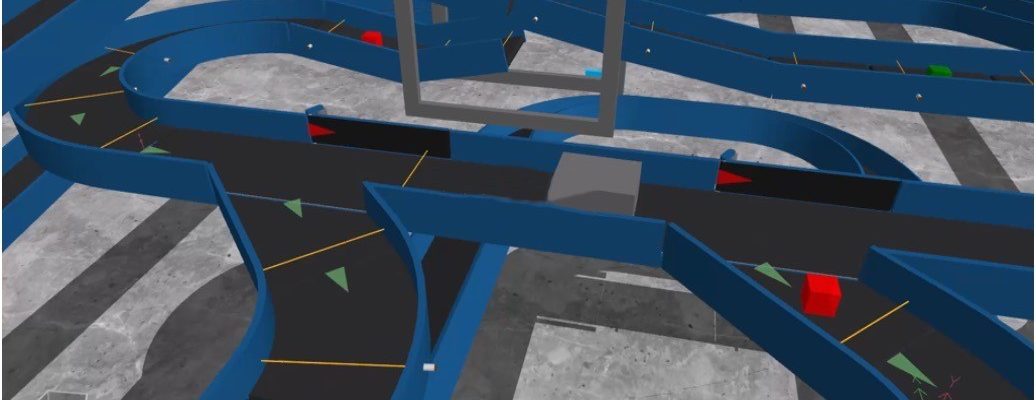

We use Emulate3D in our projects as our Virtual Commissioning platform. Emulate 3D is a software product from Rockwell Automation that digitally simulates and emulates industrial automation systems. The software’s real-time reactions make it real to life and produce a more accurate visualization of the system than other tools on the market. Emulate3D allows us to virtually test system designs and to test our code more thoroughly in-house before going into the field. The Emulate 3D software is part of our standard process in our Factory Acceptance Test (FAT).

Contact us to learn more about how we use Emulate3D as a tool to save you time and money.